Litracon Light Transmitting Concrete

Break through the concrete routine - expand the light-transmitting art living space

What is translucent concrete?

In short, translucent concrete is concrete that can transmit light.

People live in concrete houses, walk on concrete paved avenues, viaducts, and see cold and hard buildings, and people's perception of concrete is also the same.

However, we decided to give it light and art, that is, to add light and artistic elements to the concrete, combined with artistic design with translucent concrete technology to produce translucent concrete art products (such as: translucent concrete decorative panels, translucent concrete tables and chairs, translucent concrete ceiling panels, translucent concrete floors, translucent concrete stairs, translucent concrete lampshades, translucent concrete furniture and other types of custom transmissive concrete artworks).

We introduce translucent concrete from the following three aspects:

First, the material properties and characteristics of translucent concrete

Second, the application field of translucent concrete

Third, the construction process of transparent concrete

First, the material properties and characteristics of translucent concrete

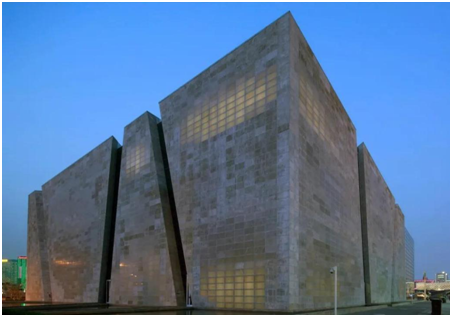

In fact, translucent cement has been used for many years, but many people do not know too much, and the intuitive understanding of it in China is the external wall application of the Italian Pavilion at the 2010 Shanghai World Expo.

The whole wall is like a huge window, the sunlight can penetrate the wall to illuminate the room, and the light can penetrate the wall to illuminate the night. So what exactly does this transparent concrete look like? Let's look down:

1. Transparent concrete raw materials

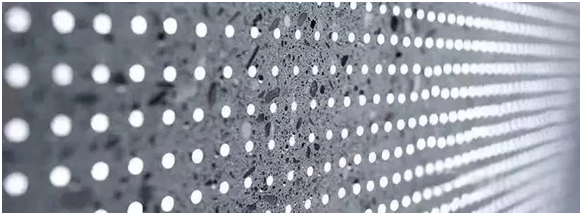

Translucent concrete is made of cement as raw material, incorporating different light-guiding materials, such as light-guide fibers and resin materials, and finally forming a modern process of transparent cement.

Large transparent concrete components require special mix ratio of high-strength, high-durability concrete, as needed to increase steel, stone, pigment and other raw materials to increase the strength and effect of concrete.

2. The optical fiber used

Commonly used optical fibers should have good light conductivity and high alkali resistance, because the material used in the light guide fiber is refracted light, not transparent light

3. The light used in transparent concrete

The light used in general translucent concrete is LED light board, light strip or lamp tube. Depending on the application scenario, the lighting effect used is also different.

4. Production process

The production process of translucent concrete: the distribution of the light-transmitting cement product mold → the light guide material→ the maintenance → the six-sided protection treatment of the polishing → surface.

5. Production style

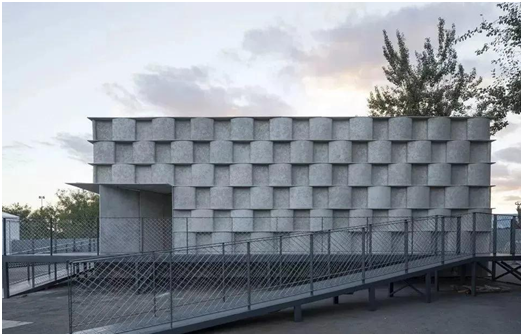

The product line of translucent concrete is rich, which can be made into slabs, bricks and other customized products.

According to the different light transmittance, surface texture, texture, light guide material arrangement, can be made of different transparent concrete panels, this plate can be directly transported to the site for installation, and finally achieve the purpose of decoration.

Second, the application field of translucent concrete.

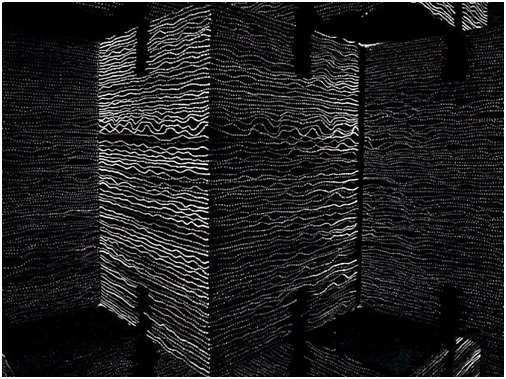

Light concrete, breaking the traditional simplicity of clear-water concrete, in the form of light and concrete combination, through the change of light, to produce multi-form and multi-style products, with its unique decoration, applied in major fields: municipal, architectural, landscape, interior decoration, home, etc.

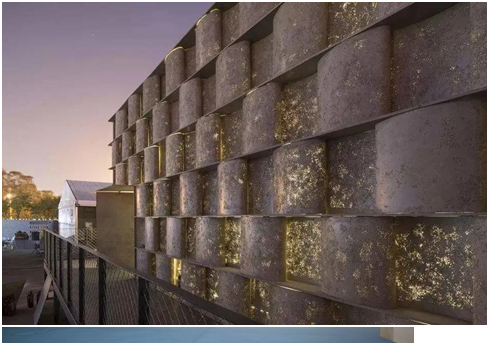

1. Application in the field of architecture

People say that the most compatible with the building facade is the "glass curtain wall", which is thin, light transmission, convenient construction, and controllable cost... But the translucent concrete introduced to you today is like a competitor of the glass curtain wall, which can not only ensure your privacy, but also ensure the lighting effect to the greatest extent, which is simply the curtain wall

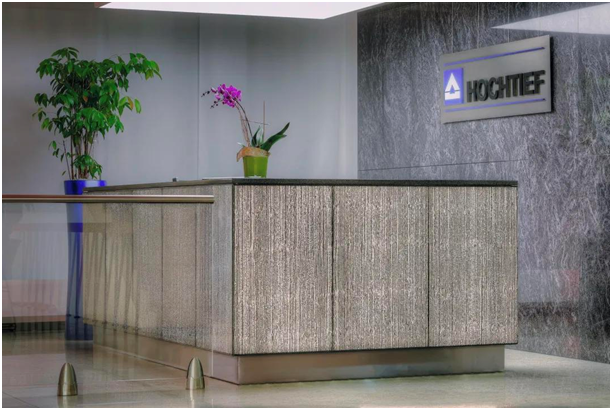

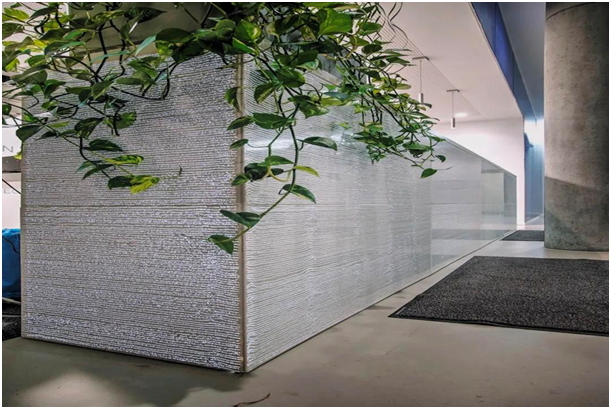

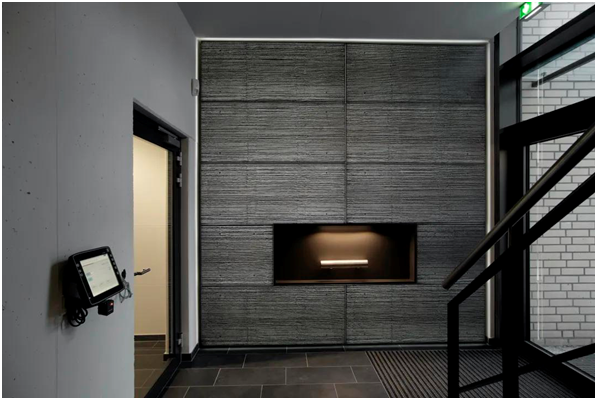

2. Indoor application

The translucent concrete with its own aura is used as a partition wall or background wall indoors, making the whole space soft and warm, and the decorations made of translucent concrete make the space lively and vivid.

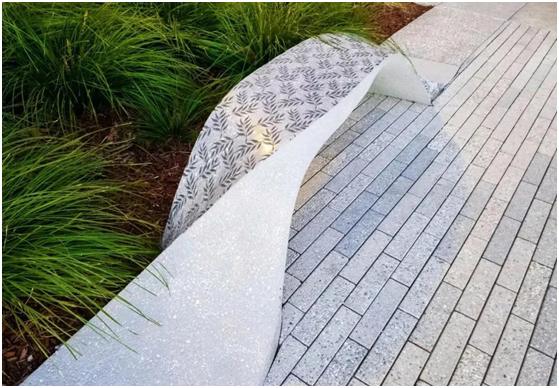

3. Application of translucent concrete in the landscape field

The transparent concrete floor is paved with a real avenue of stars, and the landscape and rest seats also reveal a little bit of stars, not dazzling, and avoid light pollution

The seats are decorated with beautiful patterns, combined with invisible lighting, transparent concrete materials, so that the entire furniture and the surrounding landscape are integrated with each other

Third, the construction process of transparent concrete

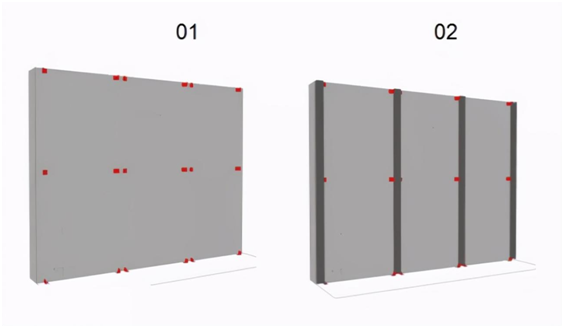

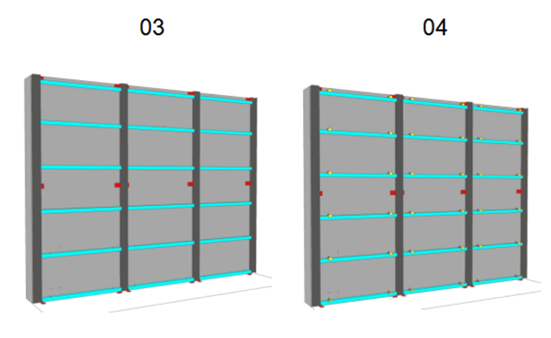

Earlier we mentioned that translucent concrete can be made into slabs, bricks and other customized products, and the corresponding construction processes are mainly divided into 2 types: dry hanging (board) and masonry (brick).

1. Dry hanging construction process

a. Carry out grassroots treatment, install steel skeleton, channel steel column;

b. Weld the keel and beam angle steel to the column

c. Pull vertical and horizontal line positioning to determine the wall plane;

d. The butterfly buckle pendant is bolted on the angle steel beam, and then - the hanging plate;

e. After filling the rubber or foam strip between the two layers of translucent plate splicing seams, the sealing mortar is applied, and the horizontal seam is first hooked, and then the horizontal seam is hooked to ensure that the seam depth is consistent;

f. Clean the finish with a rag.

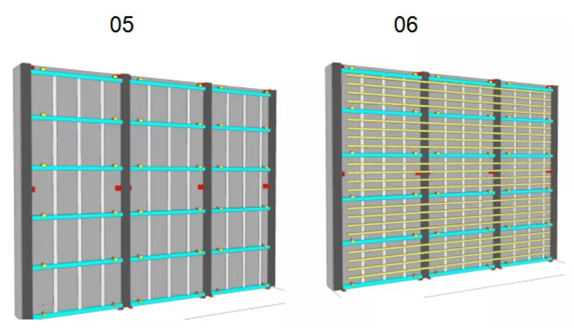

2. Masonry construction process

a. Using the cross-seam vertical brick masonry method, the number and arrangement of transparent concrete are calculated first;

b. Make the foundation bottom angle according to the arrangement of the transparent concrete slab, and the building wall adjacent to it is repaired and leveled;

c. Do a good job of waterproof layer and protective layer, use mats to level and control the elevation;

d. The structure supporting the translucent concrete must be calculated by the structure, and it should be accurately pulled up according to the on-site pulling line to avoid overturning and collapsing;

e. Use the prepared long wood chips as a horizontal fixing board, and after the first block of each row is laid, insert the gap of the fixed spacer box above;

f. Special adhesive grout (covering the fixing plate);

g. Clean the finish with a rag.

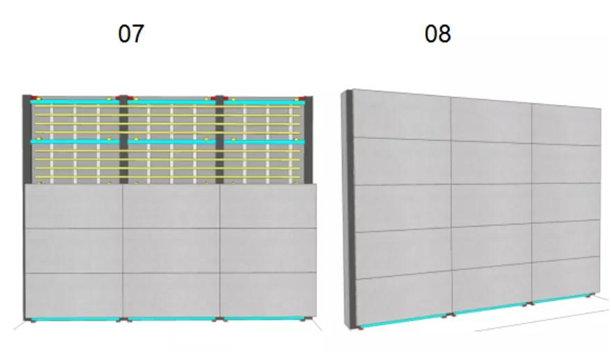

3. Knowledge supplement: How is the lighting maintenance port reserved after the installation of transparent cement?

a. If the wall is a transparent cement board, it is recommended to reserve the maintenance port in advance, and the maintenance port is on the back of the cement board wall.

b. If both or four sides are transparent cement boards, the hollow transparent cement wall access port is generally left in advance on the upper or inner side, including lamp replacement, line maintenance, etc

C, for the outdoor transparent cement stool, it is also necessary to reserve the maintenance port in advance, once fixed, this stool is difficult to move, so its light needs to be reserved in advance to repair the light, in order to later overhaul.

Shipping Container Housing Guide

Shipping container housing, also known as ISO container homes, are created out of any type of shipping container usually used for transporting goods across the globe.Why Shipping Container Housing is a Super-Hot Trend

Whether you’re looking for an intimate beachfront getaway, a compact urban abode or a larger, sprawling home on the open range, you may be able to find the perfect fit with shipping container housing. Once considered undesirable housing units for those who simply couldn’t afford the traditional brick and mortar option, storage container houses have become the hot new trend for, well, just about anyone.

ISO Container Homes Explained

While shipping containers are constructed to be used again and again, many eventually fall into disuse and end up sitting around the ports in China, northern Europe and the United States.

It is reported that an estimated 17 to 20 million of these ISO containers are peppered across the globe at any given time, with as many as 1 million of them simply sitting around taking up space.

Modern shipping container home.